Prefabricated Homes in US: 2026 Guide with Options and Pricing

Prefabricated homes, also known as prefab or modular homes, represent an increasingly popular housing solution in the United States. These structures are manufactured off-site in controlled factory environments and then assembled on the designated property. As we look toward 2026, prefabricated homes offer innovative design options, enhanced energy efficiency, and potentially significant cost savings compared to traditional construction methods.

The prefabricated housing industry has experienced remarkable growth and innovation in recent years. What once carried a stigma of being temporary or low-quality has transformed into a respected segment of residential construction. Modern prefab homes combine advanced manufacturing techniques with sustainable materials and contemporary design aesthetics. Whether you’re a first-time homebuyer, downsizing retiree, or someone seeking an affordable housing solution, understanding the current landscape of prefabricated homes can open new possibilities for homeownership.

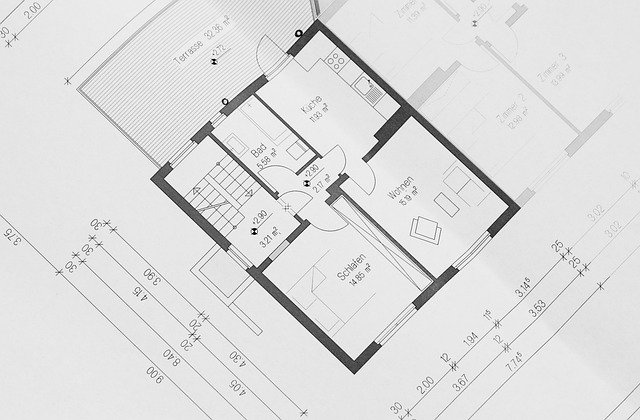

Understanding Prefabricated Home Construction Methods

Prefabricated homes are built using components manufactured in controlled factory environments before being transported and assembled on-site. Several construction methods exist within this category. Modular homes consist of multiple sections or modules built in a factory, then transported to the building site where they’re joined together on a permanent foundation. These structures must meet the same building codes as traditional homes. Panelized homes involve wall panels, roof trusses, and floor systems constructed in factories and assembled on-site, offering more customization during the building process. Manufactured homes, previously called mobile homes, are built entirely in factories on steel chassis and transported as complete units to their locations. Prefab construction offers significant advantages including reduced construction time, minimized weather delays, better quality control through factory conditions, less material waste, and often lower overall costs compared to traditional building methods.

Current Market Trends for Prefabricated Homes in 2026

The prefabricated housing market in 2026 reflects several significant trends shaping consumer choices and industry direction. Sustainability has become a primary focus, with manufacturers incorporating energy-efficient systems, solar panels, recycled materials, and advanced insulation technologies. Smart home integration is now standard in many prefab models, featuring automated climate control, security systems, and energy monitoring capabilities. The demand for accessory dwelling units has surged, with prefab companies offering compact, stylish units perfect for backyard additions or rental income generation. Urban infill projects increasingly utilize prefab construction to address housing shortages in metropolitan areas. The labor shortage in traditional construction has further accelerated prefab adoption, as factory-based production requires fewer on-site workers. Additionally, financing options have expanded, with more lenders recognizing prefab homes as permanent structures worthy of conventional mortgage products. Remote work trends continue influencing designs, with home offices and flexible spaces becoming standard features rather than optional upgrades.

Available Design Options and Customization Features

Today’s prefabricated homes offer extensive design flexibility that rivals traditional construction. Architectural styles range from modern minimalist and contemporary to farmhouse, craftsman, and traditional aesthetics. Floor plans vary from compact studios under 500 square feet to spacious family homes exceeding 3,000 square feet with multiple bedrooms and bathrooms. Exterior finishes include fiber cement siding, natural wood, metal panels, brick veneer, and stucco, allowing homes to blend seamlessly into existing neighborhoods. Interior customization options encompass flooring materials, cabinet styles, countertop selections, appliance packages, and fixture choices. Many manufacturers offer semi-custom programs where buyers select from pre-designed models then modify layouts, add rooms, or adjust dimensions within structural parameters. Fully custom prefab options exist for buyers willing to invest additional time and money into unique designs. Sustainable features such as greywater systems, composting toilets, rainwater collection, and off-grid capabilities can be integrated into designs. The level of finish varies from basic move-in ready to high-end luxury specifications with premium materials and finishes throughout.

Pricing Structure and Cost Considerations

Understanding the complete cost picture is essential when considering prefabricated homes. Base prices typically cover the manufactured home structure itself, but numerous additional expenses must be factored into budgets. Site preparation including excavation, foundation work, and utility connections can add substantial costs depending on land conditions. Transportation expenses vary based on distance from the factory to your site and the size of the home modules. Installation and assembly require crane services and professional crews. Finishing work such as connecting utilities, installing skirting, building decks or porches, and landscaping represents additional investment. Permit fees, inspections, and impact fees vary by jurisdiction but must be included in financial planning.

| Home Type | Size Range | Base Cost Estimation | Total Project Cost Estimation |

|---|---|---|---|

| Basic Manufactured Home | 1,000-1,500 sq ft | $45,000-$85,000 | $75,000-$130,000 |

| Standard Modular Home | 1,500-2,000 sq ft | $100,000-$180,000 | $150,000-$250,000 |

| Custom Modular Home | 2,000-3,000 sq ft | $200,000-$350,000 | $280,000-$450,000 |

| Panelized Home | 1,800-2,500 sq ft | $120,000-$220,000 | $180,000-$320,000 |

| Luxury Prefab Home | 2,500+ sq ft | $300,000-$600,000+ | $400,000-$800,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Cost per square foot for prefab homes generally ranges from $80 to $200 for base structures, compared to $150 to $400 for traditional site-built homes in many markets. However, final costs depend heavily on location, customization level, site conditions, and local market factors. Land acquisition represents a separate major expense that varies dramatically by region. Financing costs, insurance, property taxes, and ongoing maintenance should also factor into long-term affordability assessments.

Construction Timeline and Installation Process

One of the most appealing aspects of prefabricated homes is the accelerated construction timeline compared to traditional building. The typical process begins with design selection and customization, which can take two to eight weeks depending on complexity and decision-making speed. Manufacturing in the factory environment usually requires six to twelve weeks for modular homes, though complex custom designs may need additional time. During factory production, site preparation occurs simultaneously, including foundation construction, utility installation, and access road development. Transportation scheduling depends on manufacturer capacity and distance but typically happens within one to two weeks of production completion. On-site assembly and installation generally takes one to five days for modular homes, with crane crews setting modules on foundations and securing them together. Finishing work including utility connections, interior completion, exterior trim, and final inspections adds another two to six weeks. From initial order to move-in readiness, most prefab home projects complete within four to six months under normal circumstances. This timeline represents roughly half the duration of comparable site-built construction, which typically spans eight to twelve months or longer. Weather impacts are minimized since most construction occurs indoors under controlled conditions. Supply chain considerations in 2026 remain important, as material availability can affect production schedules. Working with experienced manufacturers who maintain realistic timelines and clear communication throughout the process helps ensure smooth project completion.

Prefabricated homes represent a practical, increasingly sophisticated housing option for diverse buyers across the United States. The combination of quality construction, design flexibility, cost efficiency, and rapid installation makes prefab housing an attractive alternative to traditional building methods. As technology advances and consumer acceptance grows, the prefabricated housing industry continues evolving to meet modern needs while addressing affordability challenges facing many Americans. Thorough research, careful planning, and working with reputable manufacturers and builders will help ensure your prefab home project succeeds and provides years of comfortable, efficient living.