New Container Houses 2026: A Look at Modern, Affordable Living

The landscape of residential architecture is evolving rapidly, with container houses emerging as a sustainable and innovative housing solution. These modern dwellings combine the durability of shipping containers with sophisticated design principles, offering an attractive alternative to traditional homes. As we approach 2026, container houses are set to revolutionize the concept of affordable living while maintaining both style and functionality. With a focus on sustainability, these homes are not just cost-effective; they also promote eco-friendly practices in construction and design, making them a preferred choice for the environmentally conscious homeowner.

Container houses are entering a more mature phase in 2026, moving from experimental projects to carefully engineered homes designed to meet Canadian codes and climates. For buyers and municipalities, the appeal lies in predictable factory fabrication, reduced site disruption, and the ability to scale from one module to many. Understanding how these structures are built, certified, and priced helps set realistic expectations about timelines, performance, and budgets in your area.

What Are Container Houses and How Do They Work?

Container houses typically repurpose ISO steel shipping containers or use modules with similar dimensions and steel construction. Builders cut openings for windows and doors, reinforce the structure, and create a high-performance envelope. In Canada, engineering is crucial to address snow loads, seismic requirements, and thermal performance. Insulation strategies often combine exterior rigid insulation with interior spray foam to reduce thermal bridging. Electrical, plumbing, and HVAC are pre-installed in the factory where possible, then connected on-site. Permitting usually follows local building codes with factory certification such as CSA A277 for modular components, plus municipal inspections for foundations and utility hookups.

Why Are Custom Prefab Homes Gaining Popularity?

Custom prefab homes are popular because they compress schedules and bring more of the quality control into the factory. Weather delays are reduced, trades are coordinated in a controlled environment, and waste is easier to manage. For homeowners, customization ranges from layout and facade choices to interior finishes. Communities see benefits too: fewer weeks of noise, traffic, and site disturbance. From an environmental perspective, reusing steel modules or efficient steel frames can lower material waste, and the compact footprints suit infill lots. That said, customization and engineering add complexity; early collaboration with designers, engineers, and local officials helps align expectations.

What Features Define Modern Container House Designs?

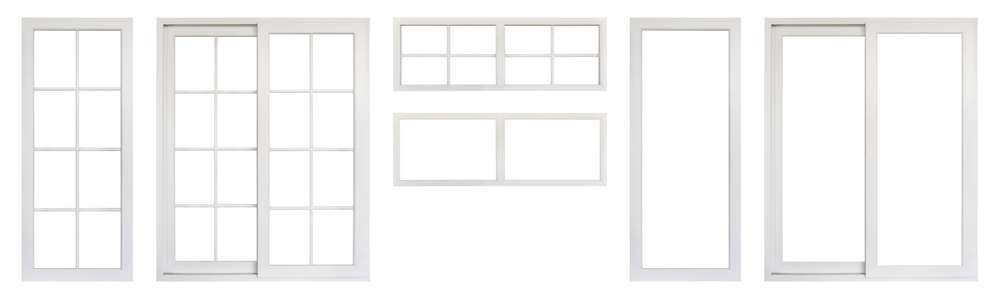

Recent designs prioritize comfort and performance. Expect high R-value assemblies suitable for Canadian winters, triple-pane windows in many climates, and continuous exterior insulation to mitigate thermal bridges. Airtightness targets are often paired with balanced ventilation using HRV/ERV systems. Noise control uses resilient channels and mineral wool, while fire safety is addressed through rated assemblies and careful detailing at penetrations. Layouts favor open living areas, built-in storage, and multi-use rooms. On-site, foundations commonly use helical piles or slab-on-grade, and craned modules minimize ground disturbance. Smart controls, heat pumps, and induction cooking are increasingly standard to reduce operational energy and improve indoor air quality.

How Do Container Houses Compare to Traditional Homes?

Compared with conventional site-built homes, container-based builds shift more labour off-site, improving schedule predictability once permits and engineering are complete. Mass and thermal performance, when detailed properly, can match code-compliant wood-frame homes, although special attention is required to prevent condensation on steel surfaces. On cost, the picture is nuanced: savings from factory efficiency can be offset by steel modifications, craning, and transport—especially in remote areas. Financing and insurance are improving but can still require additional documentation. Where these homes excel is speed, modular expandability, and the ability to deploy compact, high-quality dwellings on constrained lots.

What Are the Cost Considerations for Container Houses?

Costs depend on scope, location, and code requirements. Major drivers include container or module procurement, structural reinforcements, insulation and glazing, interior finishes, transport and craning, foundations, utility connections, engineering, and permits. In many Canadian markets, turnkey container homes commonly land near CAD 250–450 per sq ft, with remote sites or premium finishes pushing higher. As orientation, a compact 320–400 sq ft studio may total roughly CAD 110,000–200,000+, while multi-module family homes (640–1,200 sq ft) often span CAD 220,000–500,000+, excluding land. All figures are estimates; always confirm with local services.

| Product/Service | Provider | Cost Estimation |

|---|---|---|

| Single-module studio (approx. 320–400 sq ft) | Giant Containers (Toronto) | Quoted per project; many turnkey builds in Canada align with roughly CAD 250–450/sq ft. |

| Multi-module custom home (2–3 modules) | MEKA Modular (Toronto) | Typically project-based; many completed homes fall around CAD 300–500/sq ft depending on finishes and site. |

| Container-based modular building system (residential/commercial) | Ladacor (Alberta) | Project-specific; commonly in CAD 275–500+/sq ft for residential-grade specs. |

| Modern modular steel home (container-inspired) | Honomobo (Alberta) | Project-based; starting budgets for small units often exceed CAD 250k+, with final costs varying by site work and selections. |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Conclusion

By 2026, container houses and container-inspired modular systems offer a practical pathway to high-quality, factory-built housing in Canada. Their strengths lie in schedule control, consistent quality, and flexible design. Achieving comfort and durability requires careful attention to insulation, ventilation, and detailing for Canadian climates. With realistic budgeting that includes transport, craning, foundations, and permitting, these homes can deliver modern living with a smaller on-site footprint and reliable performance over time.